Our production

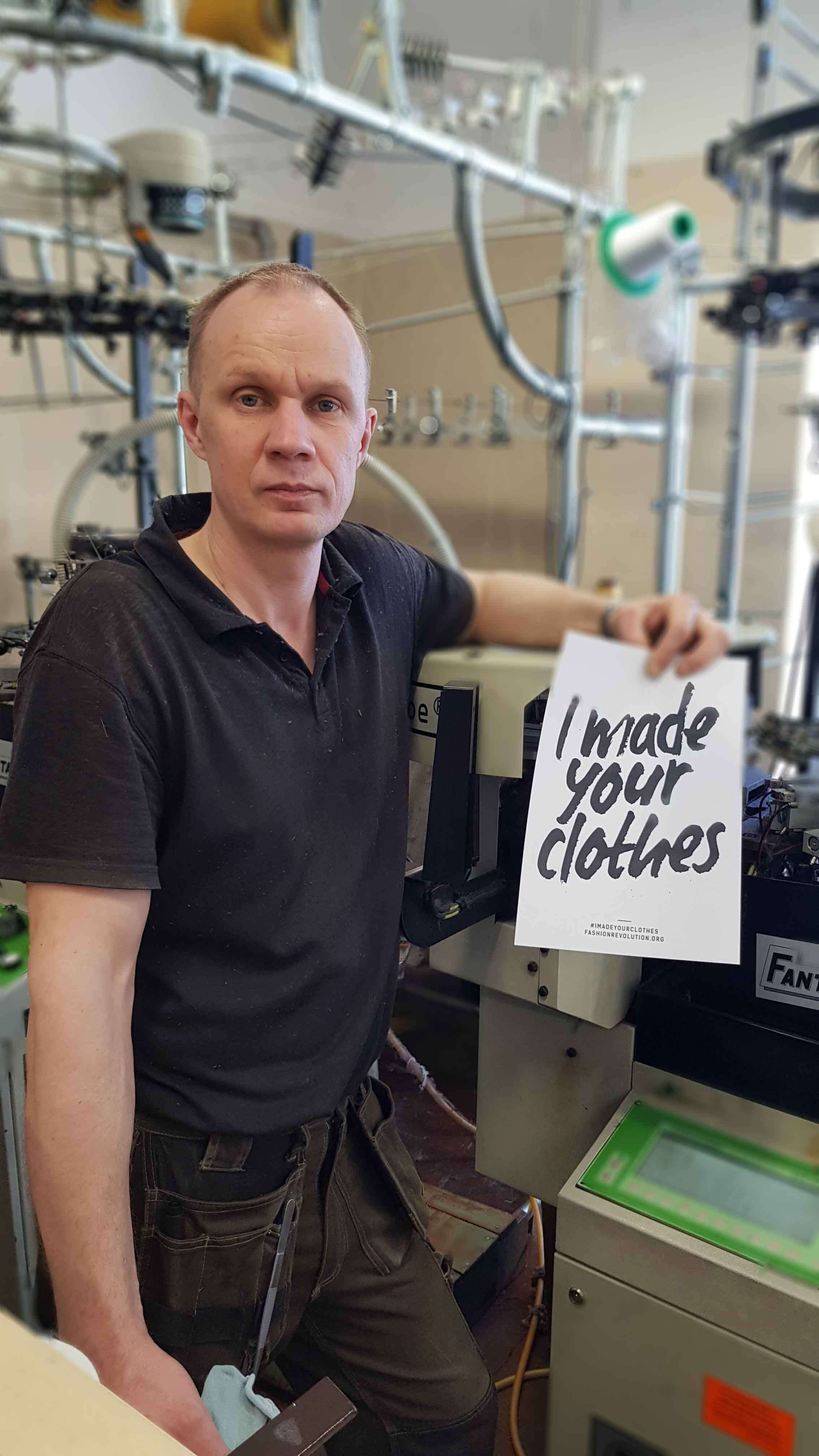

Fashion Revolution #whomadeyourclothes

Every single product from Lillelam is manufactured under good, ethical conditions. We think this is extremely important, all clothing brands can do the same!

Have you ever wondered who made your clothes? The annual Fashion Revolution campaign wants to shed light on the makers behind the garments and promote a more sustainable fashion industry.

On 24 April 2013, the Rana Plaza building in Bangladesh collapsed. More than 1 100 people died and another 2 500 were injured, making it the fourth largest industrial disaster in history.

The annual Fashion Revolution week that promotes a more sustainable fashion industry takes place on April 22-28, 2019. Fashion Revolution is a not-for-profit campaign that strives to bring forth the makers of products and improve working conditions of the garment industry. The Fashion Revolution Campaign believes that the change for the better starts with a simple question: who made your clothes?

Fashion Revolution Day was arranged for the first time on April 24, 2014 and since then Fashion Revolution, which was started by a small group of British Slow Fashion enthusiast, has engaged people worldwide who have the same mission and vision; We want a fair and pure fashion and textile industry.

Anyone who uses clothes is welcome to contribute; designers, influencers, High End stores, cotton farmers, factory workers, academics, decision makers, the media, as well as the man and woman in the street, can all contribute in their way.

One of the easiest ways you can get involved is by taking a photo of your clothing label during Fashion Revolution Week, and asking the brand #whomademyclothes?

The sustainability of operations throughout our supply chain is very important to Lillelam and we want to do our part in promoting responsibility and transparency in the garment industry.

100% of Lillelam’s products are manufactured in Europe and we are particularly concerned with working conditions throughout the value chain. We are proud of our skilled suppliers and all employees. In the spirit of the fashion revolution, we will share some stories with you.

(Due to competitor concerns we do not mention the names of the factories.)

Factory in Lithuania

The company started its business in 1999. Since then, the products have gained the trust of both Lithuanian and Western European consumers. The factory is family owned, and in these days the founder of the company, is passing on the responsibility to his son who has higher education in economics. The company has been developing and manufacturing products for well-known brands in the world since its inception. It has good and long-lasting relationships with the employees, where solid working conditions, development, flexibility and responsibility are key words for everyone.

The quality of the production is assured by a variety of organizational and quality certifications, as well as control throughout the production process.

The factory has 49 employees between the age of 20 to 67. The operational departments are knit, seam, quality control and logistics and administration. More than 50% of the employees have worked in the factories for more than 20 years.

“My name is Rimas and I enjoy producing new designs for Lillelam.”

Factory in Lithuania

The factory established for more than 50 years ago. At that time, it was amongst the factories of highest capacity among the Baltic countries; with 518 employees and with a production capacity of 841 000 products a year.

In 2017, the factory became the first company in Lithuania that officially joined the Detox campaign by Greenpeace. The company commits itself to eliminate any raw materials likely to have adverse effects on humans or the environment from all stages of the production cycle, from the start through packing, to wearing, washing, sorting and recycling of clothing by 2020. The factory closely follows Codes of Conduct, which ensures quality, environmental requirements and labor rights.

Today, there are more than 800 employees in the factory, and the average age of the workers is 46 years old. The operational departments are production, quality control, logistics, technology and innovation, sales and marketing as well as finance.

At this comparatively large factory, there are good opportunities for the employees to have personal development, such as education and innovation.

“We have been working together with Lillelam since 2015. The best part of my job is the communication between the client and our workers. I am have the main contact with Lillelam. It is always exciting to be a part of the clothes creation process. Following the steps of how the idea and the design becomes a real product and feeling like you are a part of it. This job challenge me every day so I am constantly improving”; Kristina says.

“My name is Marius and I make Lillelam in Lithuania’ | “My name is Ernesta Rinkevičiūtė, and I make Lillelam in Lithuania”

Factory in Poland

The company is family owned, with great passion for knitting. The knitting company, established in 1986, provides complete services from design to production and logistics. All production is made with great attention to details, which brings the products to the highest quality level. The production process moves from an idea to a prototype. In the next step, a program for the knitting machines is created, and the parts of the garment are knitted. Finally, the garment goes to the sewing department, where all parts are put together. This process requires great precision, which is secured by highly skilled and experienced tailors. A team of qualified and experienced employees carefully supervises the whole production process.

The team consist of 85 well skilled and passionate local employees, mainly women with the average age of 40 years. Many have worked in the company for more than 20 years. The company has invested in new machines, which are more efficient and thus environmental – friendly, as well as reduced the impact on the environment by recycling our waste. The company is also working on creating a new collection using recycled yearn.

We provide good working conditions and a safe working environment with opportunities for personal development.

One of the employees, Ms. Beata, shares her story: “I’ve worked for the company as a tailor for twenty years. Since I was a child, I have always loved sewing, so at this company I find my work fulfilling. This job gives me a lot of satisfaction. This is my dream job, and I intend to develop myself even more in the coming years.”

‘Ms. Beata’

Südwolle Group

Südwolle Group is a global family-owned company with over 3200 employees that produces worsted yarn from wool and wool blends. Based in Nuremberg, Germany, we are a global partner with manufacturing sites in Germany, Italy, Poland, Romania, Bulgaria, China and Vietnam (2019).

Environmental protection and social responsibility are key factors in everything we do. We constantly strive for more ecological production processes e.g. by developing new textile treatments like Naturetexx® Plasma for easy-care Merino without the use of chlorine, by phasing out chrome dyes in our production sites or by our clear commitment towards Zero Discharge of Hazardous Chemicals (ZDHC) requirements.

Positioned right in the middle of the textile supply chain, we are not just a yarn manufacturer, but a solution provider: We share our network and expertise to foster trust and traceability – from the sheep to the finished garment. Our goal is to deliver transparency as well as responsibly produced products that meet our customers individual needs, at the same quality level throughout the world.

Our production in Poland cultivates the local textile tradition that dates back to the 1820s. Here they have invested in a modern machine park, work conditions improvements as well as in a well-coordinated team of more than 500 employees! With over 25 years of high quality yarn production experience, we are proud that our environmentally friendly production processes are approved by 3rd party quality certificates.

Meet Agnieszka, who has worked at the spinning mill for over 20 years, ensures that our yarn is treated with passion and care. «Hi, my name is Agnieszka. I produce finest Merino yarn for Lillelam, surrounded by colleagues that are also passionate about our product. I am proud to be part of the long textile tradition of my region and happy to contribute to the future of this industry.”

www.suedwollegroup.com

https://www.instagram.com/suedwollegroup

How does Lillelam take responsibiliy?

1. How do we select our partners?

We choose our partners with care. It is never a time-pressured process when we search for a supplier. Our focus is always finding suppliers that shares our values and quality criteria’s and not to get a fast and compromising production.

We visit the manufactures in person, run meticulously through our extended checklist, and turn every stone in regards to the sustainable profile and certificates, ethical codes of conduct, security and insurance criteria, quality controls as well as subcontractors and logistic systems. The neat ensemble of suppliers we are proudly working with today, are all long lasting, true and caring relationships. We care for each other, as well as for the products we develop together.

2. How do we know what is going on?

We are passionate about what is happening throughout our value chain, and therefore we strive to have the best possible insight.

In addition to visits on site, we are daily in touch with our suppliers, and have a very nice and personal relationship to each one of them. Besides the importance of understanding our different ways of business culture and respect this, we work for common goals and long-term achievements in everything we do.

Our partners keep us constantly informed about processes and developments within their companies, as our partnerships build on common trust and interaction. We have detailed agreements that both parties have developed together, including also several licenses, checklists and agreements that has to be re-signed by the suppliers annually. It involves detailed documentation of all processes in the productions.

3. Human rights in supply chain

We exclusively support partners and companies who respect human rights and good working conditions. Additionally to our extensive Codes of conduct criteria included in our general trade agreements, we are member of IET (Initiative for Ethical Trade) and NICE (Nordic Initiative Clean and Ethical). We take part in several processes, such as CIRKit; an extensive Nordic research project, which aims to implement circular business models in companies. In this project, we disclose our supply chain as far back and as ample as possible. This gives an insight beyond the front rows of suppliers, which allows us to be able to influence and make changes and calls to actions.

Read more about Lillelams Code of conduct here. (download pdf)

Want to know more about our values? You can read more here.